JitteryMonkey

New member

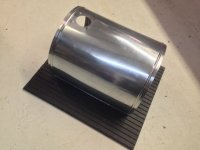

We acquired a Royal #1 Coffee Roaster recently and are in the process of rebuilding it so we can use it in our Small Town Coffee Roasters business we are starting in Rutherfordton, NC. I'm attaching some photos of the rebuild in progress and have some questions for those of you who have rebuilt vintage roasters. This roaster is going to be used daily and has the ability to roast up to 10 lbs. of coffee at a time.

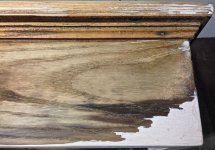

We've been quite impressed with the build quality of this early 1900's roaster. Something that took us by surprise was how screwed in fittings were actually ball-peaned from the inside to secure and prevent parts from rattling. We also found that the cast iron parts had been copper plated in the past, so we have sandblasted all parts and have had much of it copper plated again. The pieces coming back from the platters are a bit dull and we are using stainless steel hand wire brushes to buff the copper plating.

So one of the questions I have is dealing with the preservation of the copper plating with a high temperature clear coating. Our research has turned up a spray paint clear coating from VHT. The SP115 Flameproof Satin when properly cured will hold temperatures up to 2000 degrees Fahrenheit. Way more then we need, but all the other high temp finishes went up 500 degrees Fahrenheit. Does anyone have a better, tested solution?

I have other questions that I will postpone until I find other folks on this great forum that have experience on rebuilding these vintage roasters. I'll also update this thread as we progress on the rebuild. Thanks for reading...

We've been quite impressed with the build quality of this early 1900's roaster. Something that took us by surprise was how screwed in fittings were actually ball-peaned from the inside to secure and prevent parts from rattling. We also found that the cast iron parts had been copper plated in the past, so we have sandblasted all parts and have had much of it copper plated again. The pieces coming back from the platters are a bit dull and we are using stainless steel hand wire brushes to buff the copper plating.

So one of the questions I have is dealing with the preservation of the copper plating with a high temperature clear coating. Our research has turned up a spray paint clear coating from VHT. The SP115 Flameproof Satin when properly cured will hold temperatures up to 2000 degrees Fahrenheit. Way more then we need, but all the other high temp finishes went up 500 degrees Fahrenheit. Does anyone have a better, tested solution?

I have other questions that I will postpone until I find other folks on this great forum that have experience on rebuilding these vintage roasters. I'll also update this thread as we progress on the rebuild. Thanks for reading...