sdcoffeeroaster

New member

- Apr 19, 2010

- 31

- 0

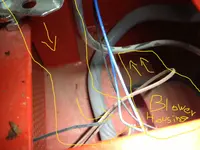

Peter: The photos I posted are pretty low-res, I pulled them from the site where it was being sold. I'll take better ones soon, with the rear plate removed so there is a view inside. I had planned to follow the ducting backwards to the drum to see if I could find any obstruction.

Gila: Do you have any photos of the exhaust port and internal ducting for your machine? I'd love to see mine has a different design, or if something is missing.

Thank you!

I think you must have something like the 2004 version shown in this picture. I can see that the upper port is plugged like yours. Maybe this person can advise you? If you remove that cover and shine a light into that port you might be able to see right to the front. If you put some sort of fan at this port I bet you will draw air thru the drum because that's how the 2009 versions work. There must be some other missing part on your roaster because there has to be some way to allow air to pass into the back of the drum (perforated) and on up thru that valve that allows the coffee to drop into the drum.

With your version the panel for removing the coffee after cooling is a much better design. I just finally removed the stirring arm on my 2009 unit and brush all the coffee out with a large pastry brush.

http://www.coffeeforums.com/forum/business-business-b2b/13185-sold-ambex-ym-2-5-roaster.html

I just found this you tube video of your style roaster. Seems like it also had a direct drive motor. I can't tell. I also don't see where they connected anything to that port so there must be some internal ducting as was described in an earlier post.

https://www.youtube.com/watch?v=wftn8yH_5vI

Last edited: