soliloquy

New member

- Feb 13, 2014

- 25

- 0

I roast on a Roaster's Authority Victory 2 that I bought in January, used. It is a bench-top type roaster.

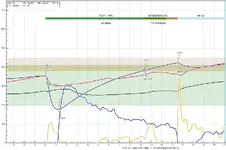

The problem I'm having is that the environmental temp never gets above 350 f during a roast, even when bean temp is over 400 f. During warm up, the ET and BT probes match up, which tells me there isn't a problem with the ET probe itself.

Maybe this isn't a problem, but I'm assuming it is, since many say that 70% of heat transfer during roasting is convection, and if my ET is lower than my BT no convection is happening.

The problem I believe is that the air going into the drum is not being heated sufficiently before entering. I've been told that air entering a Probat is heated over a 1000 f, because it is drawn across the flame bed. I've had the chance to poke around under the hood on a Probat and I noticed one major difference. The Probat's flame area is sealed off in a way. That is to say there is a metal plate under the burners. My machine does not have this, just open air down to the ground. Since there is nothing but open air under my burners, I believe the airflow entering the drum is not being directed over the flame bed and therefore is going into the drum at room temp.

Before I break out the welder and tack a plate under the burners, I thought I'd ask for opinions here first. Do most roasters have a more closed off burner area? Or is it typical to have it be wide open?

The problem I'm having is that the environmental temp never gets above 350 f during a roast, even when bean temp is over 400 f. During warm up, the ET and BT probes match up, which tells me there isn't a problem with the ET probe itself.

Maybe this isn't a problem, but I'm assuming it is, since many say that 70% of heat transfer during roasting is convection, and if my ET is lower than my BT no convection is happening.

The problem I believe is that the air going into the drum is not being heated sufficiently before entering. I've been told that air entering a Probat is heated over a 1000 f, because it is drawn across the flame bed. I've had the chance to poke around under the hood on a Probat and I noticed one major difference. The Probat's flame area is sealed off in a way. That is to say there is a metal plate under the burners. My machine does not have this, just open air down to the ground. Since there is nothing but open air under my burners, I believe the airflow entering the drum is not being directed over the flame bed and therefore is going into the drum at room temp.

Before I break out the welder and tack a plate under the burners, I thought I'd ask for opinions here first. Do most roasters have a more closed off burner area? Or is it typical to have it be wide open?